Découvrez Aquass

spécialiste du diagnostic en fatigue de vos équipements de levage

Leader en France du diagnostic en fatigue par évaluation spéciale vous propose ses compétences pour une offre globale afin de vous assister dans la maîtrise de votre parc.

Nous vous accompagnons dans la maîtrise de vos équipements de levage et de manutention, afin d’améliorer la sécurité de vos collaborateurs et garantir l’intégrité de vos engins de levage. En évaluant la durée de vie résiduelle de vos équipements nous contribuons à la prévention des risques dans la manutention.

Avec Aquass, de l'assistance à la maitrise d'ouvrage en passant par l'assistance technique et nos solutions digitales pour monitorer vous-même vos engins de levage, nous sommes à vos côtés durant tout le cycle de vie de vos équipements.

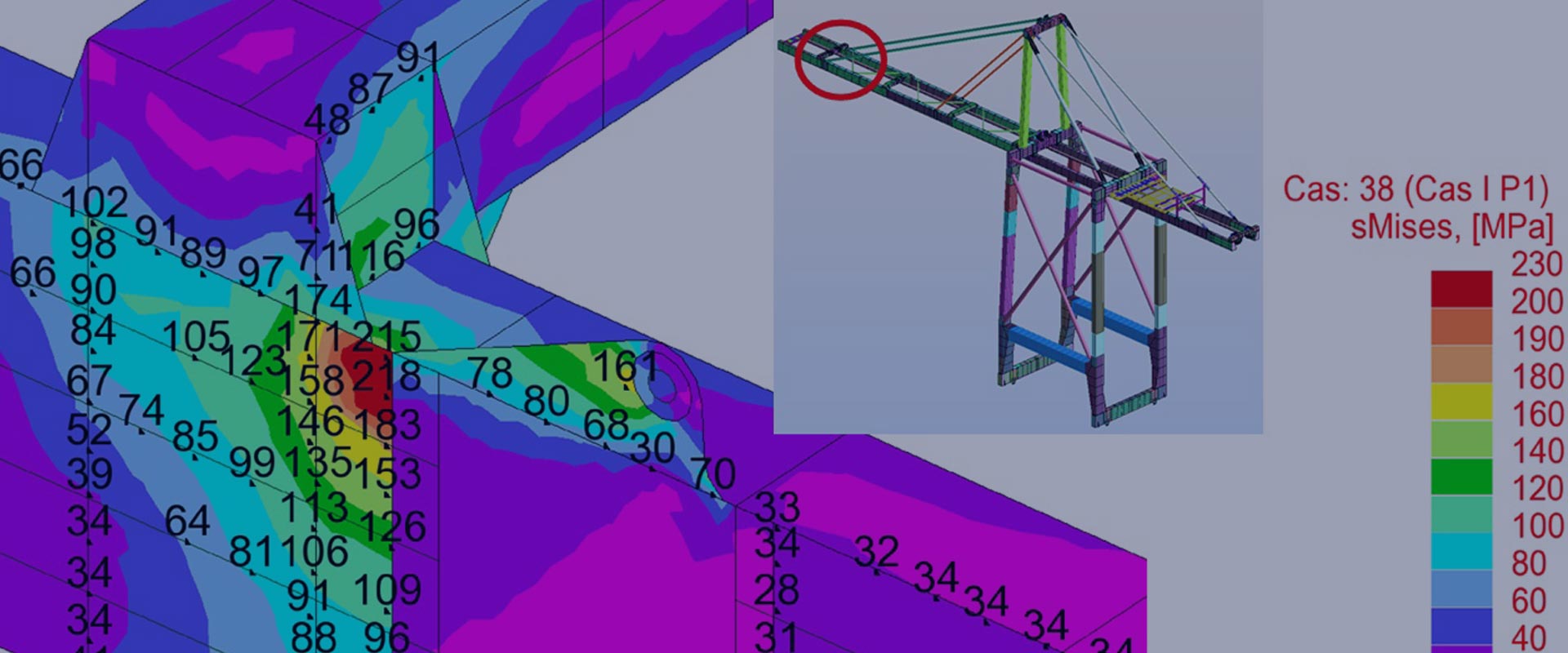

Modélisation et calculs des contraintes et

Identification des assemblages et organes critiques

Le levage

notre spécialité depuis plus de 25 ans

Depuis 1995, nous accompagnons les entreprises portuaires pour inspecter et établir les contraintes en résistance et les contraintes en fatigue des équipements de levage de tous type, portiques à containers ou à vrac, les grues portuaires, les ponts de coulée, les appareils à sécurité renforcée (nucléaire), les ponts roulants, les grues à fléchette,...

Nos ingénieurs vous apportent la garantie de calculs et modélisations précises pour monitorer vos équipements. Répondre aux enjeux de la sécurité de vos équipes et de la productivité de vos activités de manutention, est notre ligne directrice.